Description du produit:

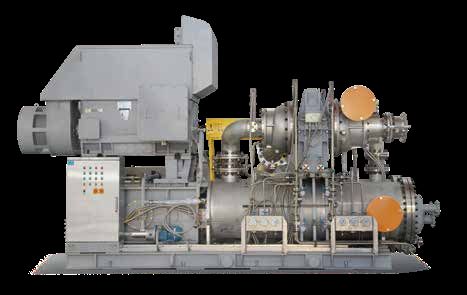

L'unité de compresseur centrifuge est un équipement de compression de gaz efficace, économe en énergie et fiable qui adopte une conception aérodynamique avancée et des processus de fabrication de précision.Il convient à des domaines tels que la pétrochimieCette unité présente les caractéristiques d'un débit élevé, d'une pression élevée, d'une faible consommation d'énergie,et contrôle intelligent, qui peut répondre aux besoins de compression de différents scénarios industriels.

En 2012, l'entreprise a collaboré avec des universités pour concevoir et produire le premier prototype d'unité de compresseur centrifuge.Il a maintenant développé des unités de compresseurs centrifuges de dizaines de modèles sur 9 plates-formes de petits à grandsLes milieux compressibles tels que l'air, l'argon, l'azote, la vapeur d'eau, etc. peuvent être comprimés en étapes de un, deux, trois, quatre, cinq et six.

Avec l'amélioration continue de la qualité technologique, en s'appuyant sur de solides capacités de recherche et développement, des centres de fabrication avancés et un service après-vente complet.La centrifugeuse d'Aipu est sûre de devenir une marque de classe mondiale.

Principaux avantages:

L'allocation optimale du rapport de compression entre les étapes, tous les composants pneumatiques sont calculés et vérifiés à l'aide d'un logiciel CFD avancé et vérifiés par des essais réels.La plage de réglage du volume de gaz est large, et une efficacité élevée peut être atteinte à la fois dans des conditions de conception et de fonctionnement variables.

Conception personnalisable des rouleaux et des diffuseurs pour maximiser l'efficacité aérodynamique

L'efficacité de fonctionnement des centrifugeuses est fortement affectée par l'environnement et il peut y avoir des écarts entre la conception et les conditions de fonctionnement réelles.Les composants de compression centrifuge conçus par lots à travers des modèles ne peuvent pas obtenir la correspondance des points de conception avec les points de travail réels de chaque utilisateur, entraînant l'incapacité des utilisateurs à atteindre une efficacité optimale et le gaspillage d'énergie lors de l'utilisation réelle.La centrifugeuse Kaishan peut personnaliser les composants de compression pour chaque utilisateur en fonction de leur température sur place, les conditions de pression atmosphérique, d'humidité et de température de l'eau de refroidissement, combinées au débit et à la pression réels d'air comprimé requis par le processus de production,pour s'assurer que les conditions de conception correspondent pleinement aux conditions sur placeCette méthode de conception et de fabrication améliore considérablement le fonctionnement pratique de la centrifugeuse.

Efficacité, économie d'énergie.

Diffuseur

L'adoption d'une conception de diffuseur à lame en forme d'aile à faible viscosité peut améliorer l'efficacité de la pression statique du compresseur et élargir la plage de régulation du débit.

Ventilateur à volet guide d'entrée (VVIG)

L'actionneur électrique entraîne des lames moulées de précision en acier inoxydable et le système de commande ajuste automatiquement l'ouverture de l'IGV en fonction du volume d'air requis par l'utilisateur.

Le moteur à impulsion

Conception efficace de lames de flexion à trois éléments, fraisage intégré avec centre d'usinage CNC à cinq axes, haute précision, efficacité aérodynamique plus élevée que les rouleaux moulés,et plus résistant à la fatigue et durableChaque roue est soumise à un équilibrage dynamique strict, à un test de rotation de 115% et à un test non destructeur pour s'assurer que le produit est entièrement qualifié.

Système de scellement

Conception d'un système d'étanchéité fiable, fournissant 100% d'air comprimé sans huile

Sceaux à huile: anneau de blocage à huile et sceau labyrinthique.

Sceaux à gaz: En adoptant un joint à anneau flottant de carbone spécialement conçu, la fuite est faible et il n'est pas nécessaire d'alimenter en gaz d'étanchéité externe, ce qui améliore la fiabilité opérationnelle.

Équipement

Acier allié forgé, surface des dents carburée et finement broyée, qualité AGMA13, engrenage hélicoïdal unidirectionnel, force uniforme, capacité de roulement élevée et faible bruit.La boîte de vitesses adopte une structure de section horizontale pour une inspection et une maintenance faciles.

Anneau de poussée

La poussée axiale du rotor de la roue adopte une structure avancée d'anneau de poussée et un anneau de poussée à face dure de haute précision, ce qui minimise les pertes mécaniques dans la mesure du possible.Comparé aux roulements de poussée, l'efficacité énergétique peut être améliorée jusqu'à 3% et la fiabilité des surfaces de contact mous est plus élevée.

Le roulement

En adoptant des roulements à plaquettes d'inclinaison en 5 pièces, le centre de l'arbre est réglé automatiquement en fonction des changements de charge et de température pour s'adapter à la déformation de l'arbre et aux erreurs d'alignement,assurer le fonctionnement stable du rotor dans diverses conditions de travail.

Surveiller la température de chaque roulement pour assurer un fonctionnement fiable du compresseur.

Accouplement

En adoptant des accouplements souples laminés en acier inoxydable, il n'est pas nécessaire d'ajouter régulièrement de la graisse lubrifiante, ce qui permet d'obtenir un véritable entretien libre et équipé de couvercles de protection de sécurité.

Filtre à double huile (facultatif)

Un double filtre à huile avec une soupape de commutation, qui peut remplacer en continu l'élément filtrant en ligne sans arrêter la machine.qui signale le remplacement de l'élément filtrant lorsqu'il est obstrué ou que la différence de pression entre l'entrée et la sortie est trop importante.

Conception de la pompe à huile de débordement

En cas de panne soudaine de courant dans l'usine, la pompe d'huile principale conçue pour le débit d'huile peut assurer l'arrêt sûr de l'unité.

Un refroidisseur

L'intercoolant adopte une structure d'échangeur de chaleur à tube droit avec un démontage et un nettoyage faciles à l'intérieur du tube d'écoulement d'eau et à l'extérieur du tube d'écoulement d'air.d'une épaisseur n'excédant pas 50 mm, et les nageoires sont traitées anti-corrosion, avec une longue durée de vie de conception.

La surface intérieure du conduit de circulation de l'air du refroidisseur est traitée avec des mesures anti-corrosion spéciales pour éviter toute contamination de l'air.

Système de contrôle avancé

L'interface de fonctionnement chinoise, le contrôle PLC convivial et la conception de l'écran tactile LCD conviviale offrent un affichage de panneau plus intuitif, un fonctionnement facile,et la surveillance en temps réel des paramètres tels que la température, la pression et les vibrations à l'intérieur de l'unité.

L'alarme automatique et la protection contre l'arrêt par blocage assurent la sécurité du compresseur.

La méthode de communication standard Modbus permet une communication à distance facile avec le système informatique supérieur.

Un système de commande par blocage de plusieurs machines (en option) peut être fourni pour obtenir un contrôle centralisé de plusieurs compresseurs.

Voltage constant et double commande automatique

Le compresseur centrifuge adopte une méthode standard de régulation de la pression constante pour maintenir le système utilisateur à un point de pression stable,prévention des fluctuations de pression causées par des changements de la demande de gaz du système.

Le double contrôle automatique permet aux utilisateurs d'économiser au maximum l'énergie et l'électricité lors de l'utilisation intermittente du gaz.

Protéger contre les surtensions

Le régulateur surveille la fluctuation de la pression du compresseur, et si la fréquence et l'amplitude de la fluctuation dépassent les valeurs prédéfinies, le compresseur déclenche une alarme et protège automatiquement.Cette méthode a un effet anti-surge plus direct et un temps de réponse plus rapide.

Les changements de température extérieure et d'autres conditions peuvent entraîner des changements dans les caractéristiques de surtension du compresseur,et la technologie de compensation automatique de la dérive de la ligne de surtension peut automatiquement compenser les changements dans les caractéristiques de surtension du compresseurPar conséquent, la plage maximale possible de réglage du fonctionnement du compresseur peut être fournie en fonction des conditions de fonctionnement réelles, ce qui permet aux utilisateurs d'économiser beaucoup d'énergie.

Applications:

Assistance et services:

Nos produits de compresseurs de gaz de processus fournissent un soutien technique complet et des services pour s'assurer que nos clients sont satisfaits de leurs achats.Notre équipe d'experts peut fournir une assistance pour l'installationNous fournissons également des services de réparation et de remplacement de pièces ou de composants défectueux.y compris les composants de base tels que les moteurs, enveloppes, rouleaux, roulements, joints d'air, joints d'huile, vannes, ainsi que les filtres à air conventionnels, filtres à huile, graisse lubrifiante, huile lubrifiante, etc.Nous fournissons également des ressources de formation et d'éducation pour aider les clients à maximiser les performances et la durée de vie de leurs compresseurs centrifuges.

Emballage et expédition

Emballage du produit:

LeGaz de procédéle compresseurIl est livré dans une boîte en carton robuste avec l'image du produit et les spécifications imprimées à l'extérieur.le produit est bien emballé avec des inserts en mousse pour éviter tout dommage pendant le transport.

Pour la navigation:

Notre délai d'expédition standard est de 3 à 5 jours ouvrables. Pour une expédition accélérée, veuillez contacter notre service clientèle. Nous expédions par des transporteurs de confiance tels que UPS, FedEx,et USPS et fournir un numéro de suivi pour votre commodité.

FAQ:

Q: Quelle est la marque de ce produit?

R: La marque de ce produit est Aipu.

Q: Quel est le numéro de modèle de ce produit?

R: Le numéro de modèle de ce produit estGaz de procédéle compresseur.

Q: Où ce produit est-il fabriqué?

R: Ce produit est fabriqué en Chine.

Q: Ce produit a-t-il des certifications?

R: Oui, ce produit est certifié par ce.ul.

Q: Quelle est la quantité minimale de commande pour ce produit?

R: La quantité minimale de commande pour ce produit est de 1pc.

Q: Le prix de ce produit est-il négociable?

R: Oui, le prix de ce produit est négociable.

Q: Quels sont les détails de l'emballage de ce produit?

R: Les détails de l'emballage de ce produit sont contenant.

Q: Quelle est la durée de livraison de ce produit?

R: Le délai de livraison de ce produit est de 10 jours.

Q: Quelles sont les conditions de paiement pour ce produit?

R: Les conditions de paiement pour ce produit sont tt.

Q: Quelle est la capacité d'approvisionnement de ce produit?

R: La capacité d'approvisionnement de ce produit est de 10000 t/an.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!